SATURN builds CUSTOM wire rope hoists, tractor drives, crane systems and related components for different environments including hazardous, high temperature and corrosive/clean room environments. Air-powered features are available for hoists and tractors.

HAZARDOUS ENVIRONMENTS

SATURN builds wire rope hoists, tractor drives, crane systems and related components for hazardous environments where flammable gases and/or dusts are or may be present. OWNER/DEALER is responsible to provide accurate HAZARDOUS Location CLASSIFICATION for working area of all NEW equipment.

- Class I, Groups C & D and/or Class II, Groups E, F & G Environments

- DIV 1 or DIV 2 Locations

- Indoors or Outdoors

- UL Certified Motors, Brakes and Control Enclosures Per Location

- Intrinsically Safe N4 Controls Devices (Pendant, Limit Switches)

- ALL Electrical Conforms to NFPA 70 (National Electric Code)

- Rigid Conduit/Flexible MC-HL Power Cable As Required

- Spark Resistant Mechanical Features Are Optional

- Stainless Steel or Bronze Wheel

- Stainless Steel Wire Ropes

- Stainless Steel Guide Rollers

- SS Tow Bars/Drive Chains

- Spark Resistant Hook Blocks

- Spark Resistant Electrification

- Rubber Bumpers

- Bronze Hooks

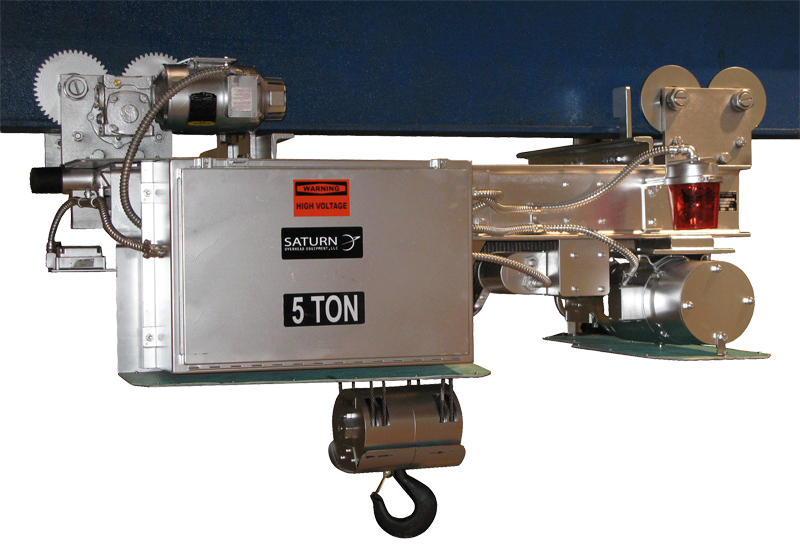

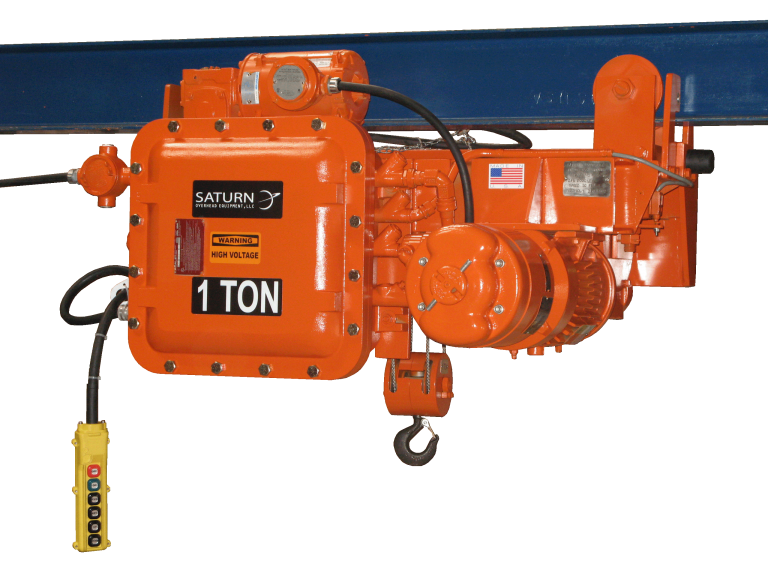

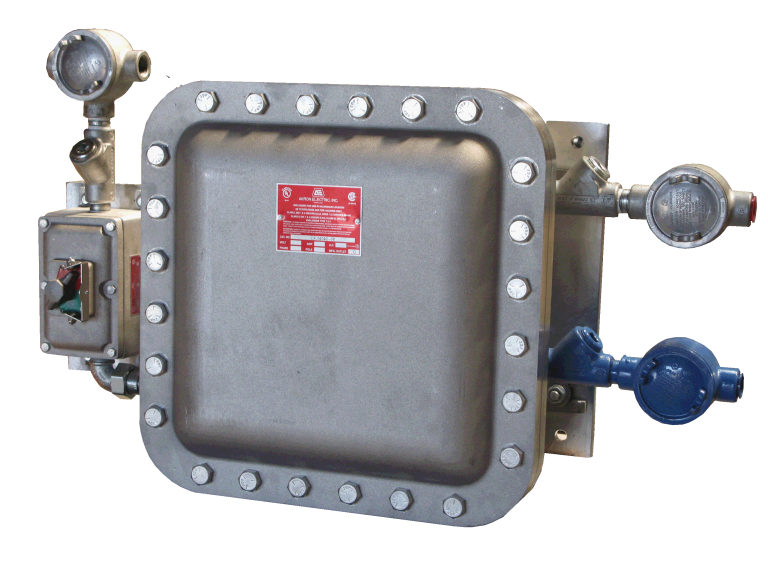

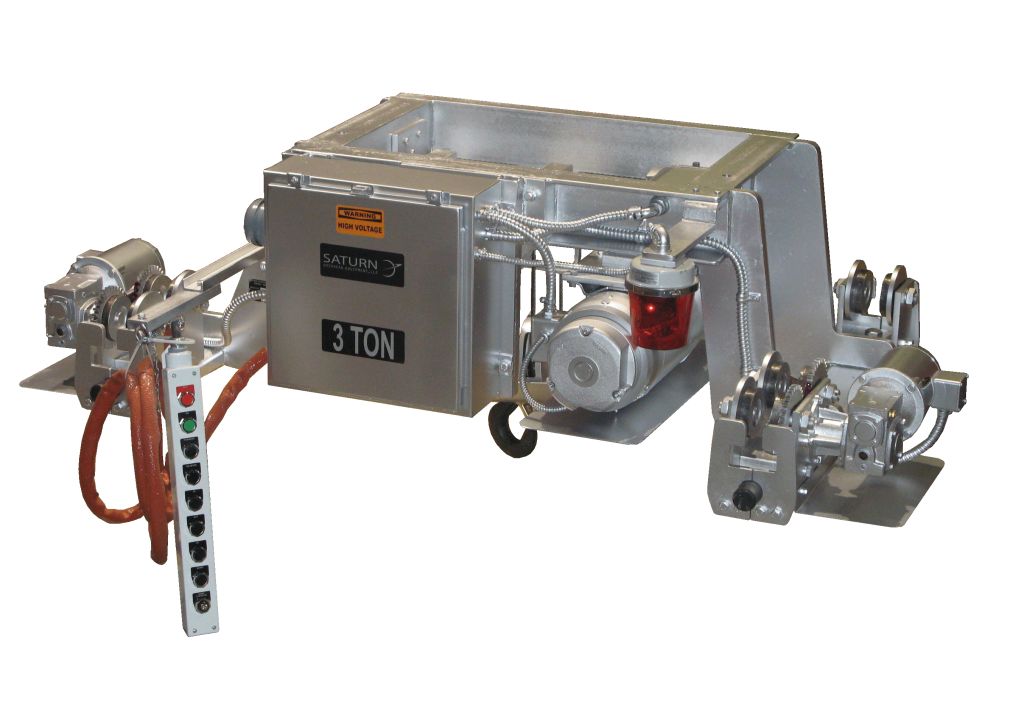

EXPLOSION PROOF HOIST WITH

INTRINSICALLY SAFE PENDANT

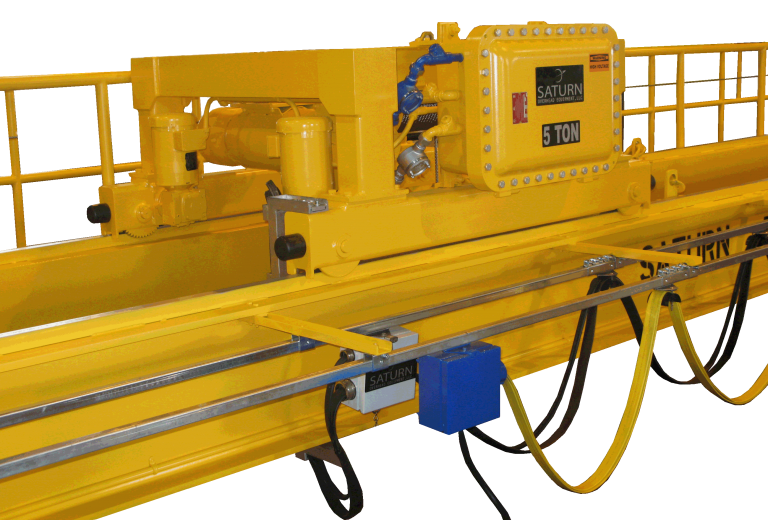

EXPLOSION PROOF CRANE SYSTEM

AND BRIDGE PANEL

AND BRIDGE PANEL

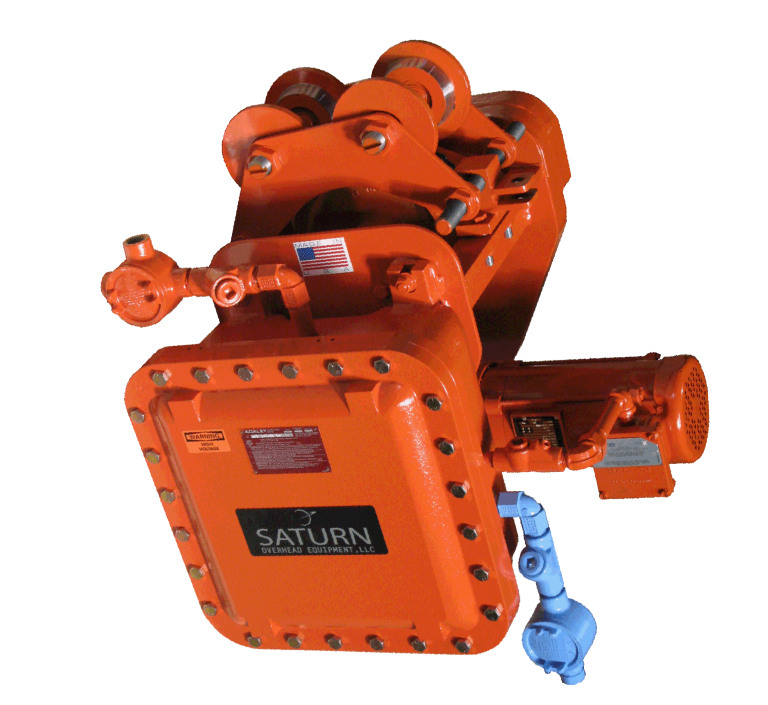

EXPLOSION PROOF

LOW HEADROOM HOIST

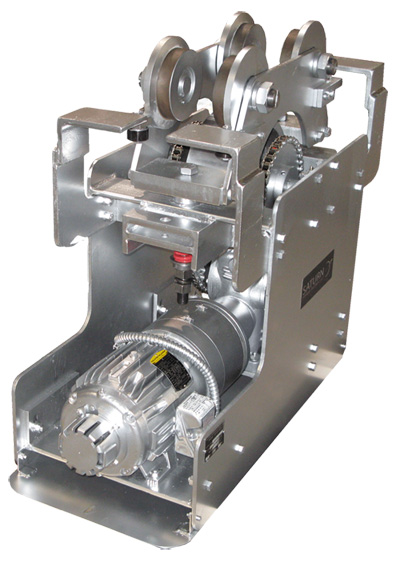

EXPLOSION PROOF DRIVE TRACTOR

HIGH TEMPERATURE ENVIRONMENTS

SATURN engineers and manufactures wire rope hoists, tractor drives and related overhead crane equipment for operation in high-temp environments where temperatures may exceed 120F. This includes hoists that handle hot molten metal. SATURN Hot Metal Hoists meet the Safety Requirements for Molten Metal Handling and Pouring Equipment as per ASTM E2349-05/9.5 (Supersedes ANSI Z241.2).

STANDARD FEATURES FOR HOT METAL HOISTS

- Conforms to OSHA 1910.179 Safety Standards

- Hoist Worm Gear Drive (As 2nd Mech. Braking Means)

- Wire Rope With 8:1 Safety Factor

- Metal Power Circuit Upper Limit Switch

- Metal Gear Type Limit Switch (2nd Upper & Lower Limits)

- Warning Light & Horn To Signal Trolley/Bridge Motions

- Class H Insulated Motors and Brake Coils

- Heat Shields Underneath Mechanical Drives

- Heat/Splatter Shield Underneath Hook Block

- NEMA 12 Enclosures With High-Temp Internal Wiring

- Motor/Circuit Protection with Motor Thermostats

- High-Temp External Wiring Thru Metal Conduit

- Metal/N12 Pendant with Fire Sleeve Cord Cover

- Oversized Hook To Properly Fit Ladle Bail

- High-Temp Synthetic Oil in all Reducers

- High-Temp Grease in all Bearings

- High-Temp Aluminum Paint

- Drop Lugs & Rubber Bumpers

- Mainline Contactor

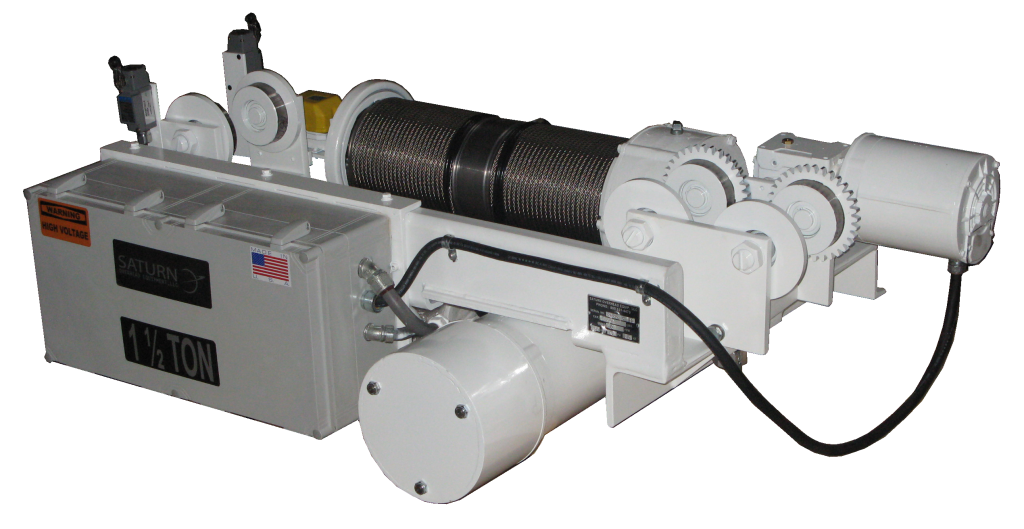

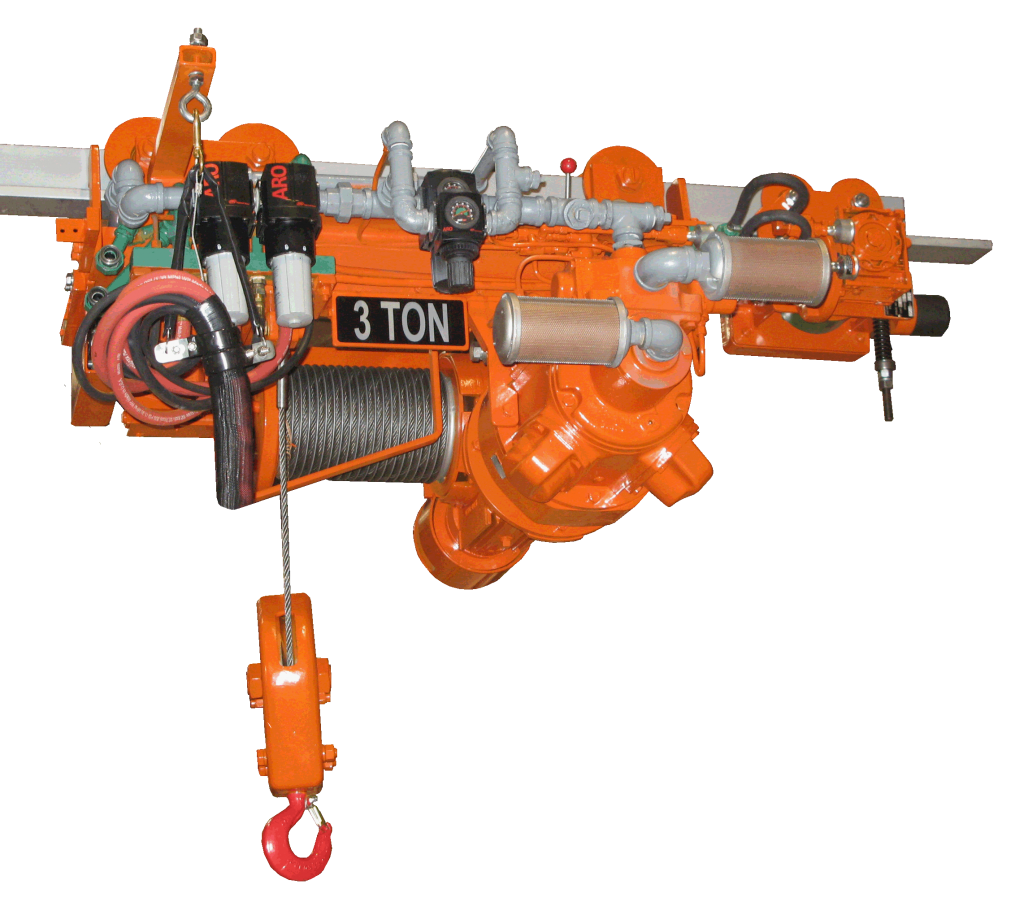

3-TON RAISED HOT DUAL RAIL

HOT METAL HOIST

3 TON HOT METAL HOIST

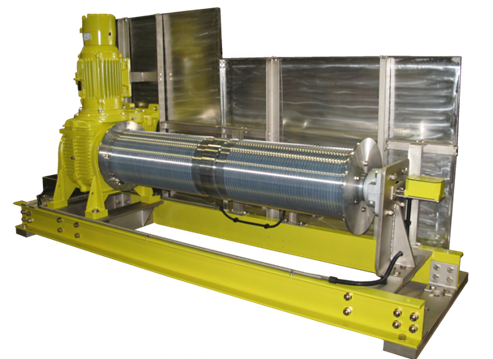

CORROSIVE/CLEAN ROOM ENVIRONMENTS

SOME COMMON FEATURES

- STAINLESS STEEL Components: Wheels, Gears, Drums, Sheaves, Cables, Hooks & Lower Blocks

- Chains, Sprockets, Shafts/Pins/Axles, Bearings, Framework, Nameplates & Hardware

- ELECTRO-LESS NICKEL PLATED Components (Cost Effective Alternative to SS)

- NYLON/PLASTIC-PVC/FIBERGLASS Components

- Stainless Steel/Non-Metallic Electrical Conduit/Fittings

- NEMA 4X (Stainless Steel) Enclosures

- Stainless Steel or Painted Drip PanS

- Non-Metallic Limit Switches

- TENV/Severe Duty Motor

- FDA Oils, Greases & Paints

- Epoxy Paint

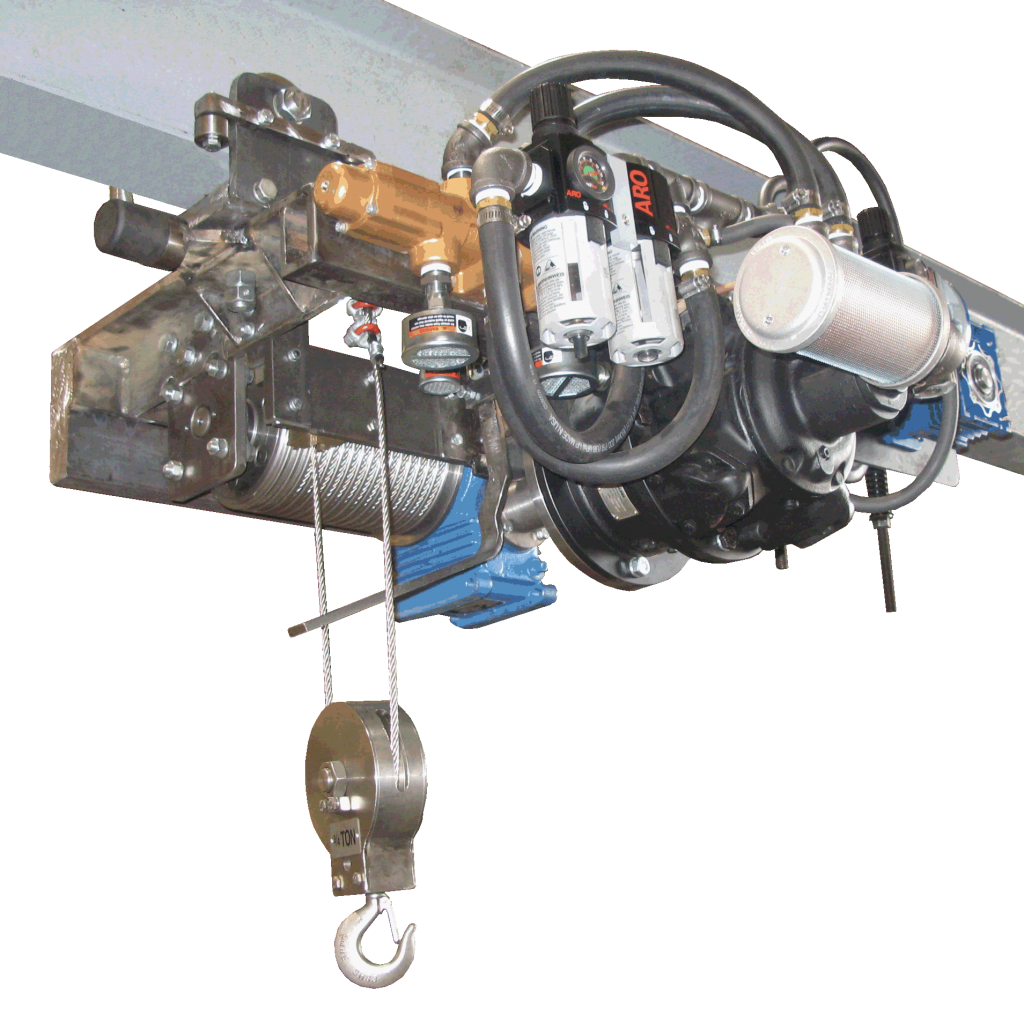

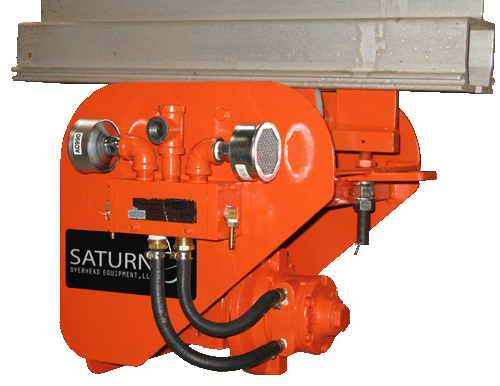

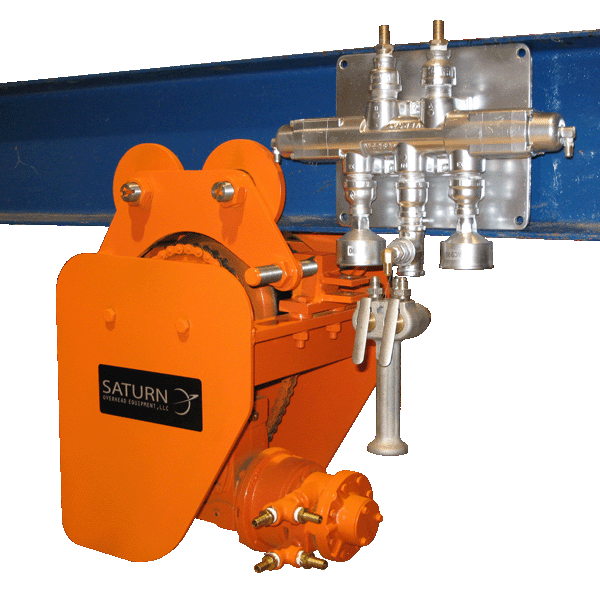

AIR POWERED EQUIPMENT

SATURN builds air powered equipment where electric power is not present. SATURN Air Hoists meet or exceed the performance standards for overhead air wire rope hoists as per ASME HST-6 as well as the safety standards for overhead hoists as per ASME B30.16.

AIR HOISTS

- Up to 3-Ton Capacity

- Single Speed Hoist Control (Only)

- Single or Variable Speed Trolley

- With Filter, Regulator, Lubricator

- With 4-Lever Air Pendant

- Optional Spark Resistant Features

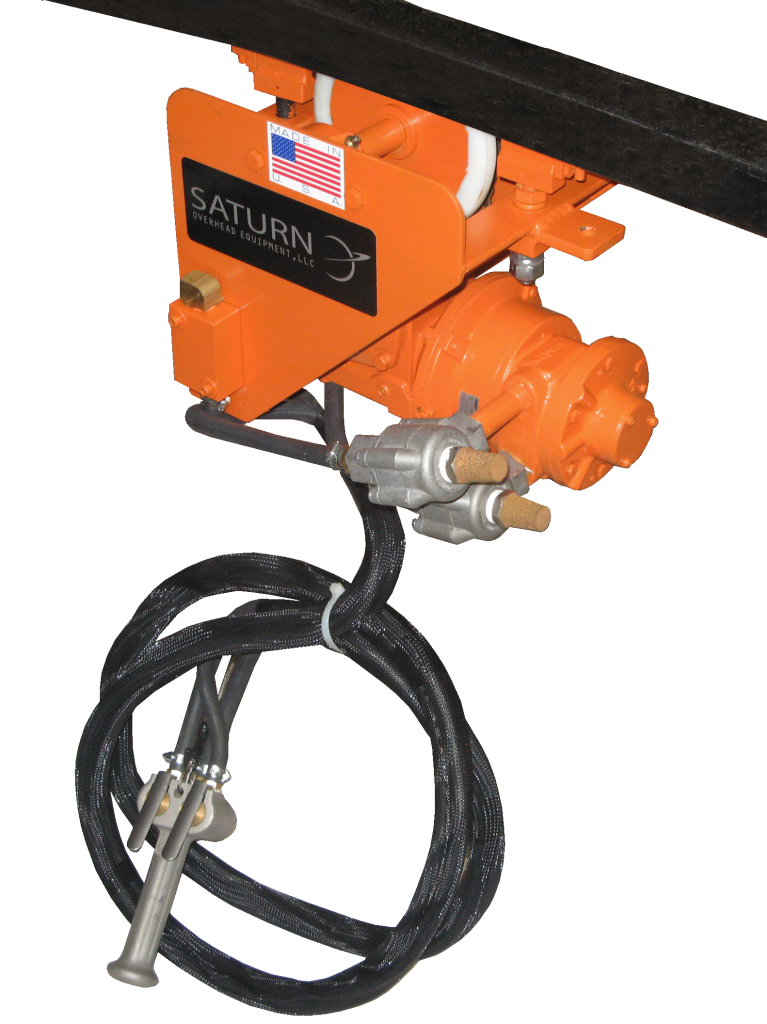

AIR TRACTORS

- Bridge and/or Trolley Tractors For All Track Types

- Single or Variable Speed Controls

- Optional 4-Lever Air Pendant

- Optional Coiled Air Supply Hoses

- Optional Spark Resistant Features