All SATURN hoists utilize high-ratio Worm Gear Drives which are inherently self-locking and typically cannot be back-driven. This provides a safe secondary mechanical braking means to hold and control the load which is well-recognized as such by the industry. Hoist Worm Gear Drives can hold a load for infinite periods of time as well as handle long lifts without problems unlike a standard load brake which can heat up and wear out. Hoist Worm Gear Drives, with less moving parts and no required adjustment, have proven to be lower in maintenance in contrast with alternative hoist drives which generally involve multiple gear sets in addition to a mechanical load brake.

MECHANICAL PARTS

SATURN component parts are the building blocks of our top quality equipment. SATURN component parts are manufactured in our in house fabrication and machine shops. Most of these items are also readily available as we do stock thousands of dollars in inventory to best serve our ever-growing family of machinery operating in the field. Please take the time to learn a little more about SATURN components as we have several key items on display below. SATURN component parts can be purchased for existing SATURN machinery or separately to fit a wide variety of independent material handling applications. For further information about these items or other SATURN components, please consult our office.

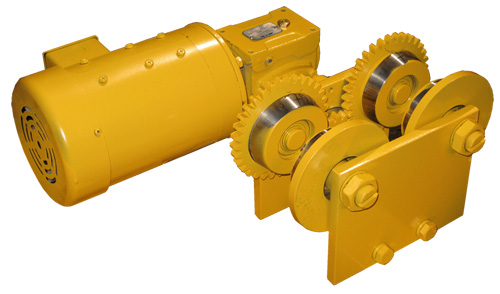

STANDARD MOTORIZED TROLLEY

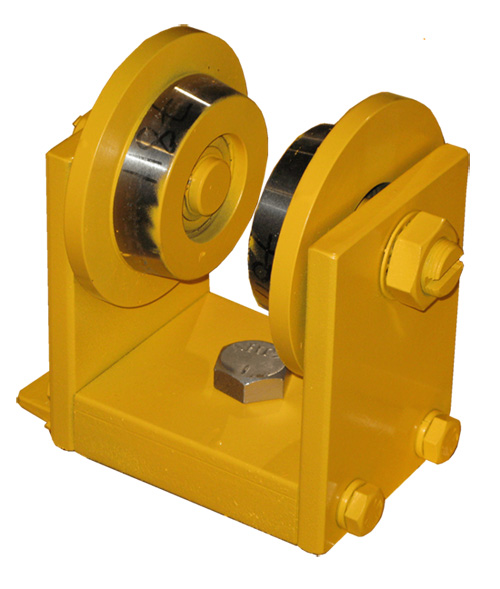

2-WHEEL PLAIN TROLLEY

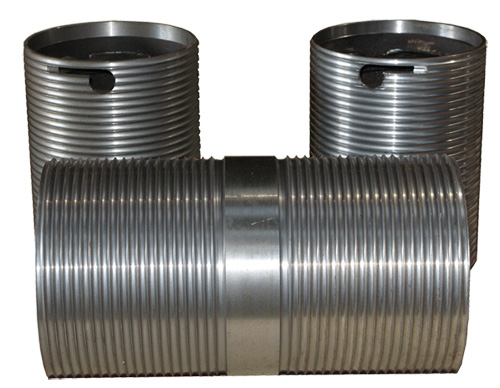

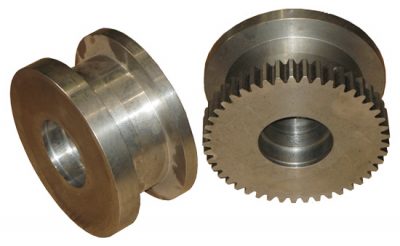

MACHINED STEEL HOIST COMPONENTS

MACHINED STEEL HOIST DRUM

MACNINED STEEL ENDTRUCK WHEELS

CONTROL PACKAGES

SATURN offers various Control Packages for all our Hoist and Crane Equipment. Whether it is Standard or Custom, SATURN can build the control panel of your choice.

(VFD) Control Packages are slowly becoming very popular and are almost standard on all new equipment these days. The benefits of (VFD) Controls by far outweigh its initial costs. (VFD) Controls allow the operator to precisely and safely control the load. Acceleration and deceleration rates and 2-speed control limits are all set to best support the given application. Any wear induced on mechanical parts over time when using (VFD) Controls is much less.

Please see our photos below for further reference on SATURN control panels.

PANEL WITH VFD HOIST AND TROLLEY CONTROLS

CUSTOM CONTROL PANELS

CUSTOM CONTROLS WITH RADIO

WORM GEAR

SATURN uses Worm Gear Drives on all its Wire Rope Hoists, Drive Tractors and Bridge Crane End Trucks as standard. Worm Gear Drives are rugged and reliable and offer smooth and quiet operation.

Due to their inherent friction, Worm Gear Drives also act very similar to brakes by retarding motion. For that reason, brakes are generally NOT required on all SATURN Worm Gear Trolleys, Drive Tractors or End Trucks. Heavy capacity, high momentum systems operating without VFD controls are sometimes the exception. In these cases, the trolley or crane may roll more than the acceptable limit without a brake.

For High-Ratio Worm Gear Hoists, there are some major advantages over other hoists.

- High-Ratio Worm Gears safely control the lifting load without the need for a Mechanical Load Brake.

- High-Ratio Worm Gears are inherently Self-Locking thus these hoists are very capable of acting as 2nd stopping brake and also holding up a load.

- Worm Gear Hoists have very Low Maintenance as fewer moving parts lead to fewer repairs

- High-Ratio Worm Gear Hoists Conform to CMAA, ASME and OSHA guidelines

- High-Ratio Worm Gears safely control the lifting load without the need for a Mechanical Load Brake.

- High-Ratio Worm Gears are inherently Self-Locking thus these hoists are very capable of acting as 2nd stopping brake and also holding up a load.

- Worm Gear Hoists have very Low Maintenance as fewer moving parts lead to fewer repairs

- High-Ratio Worm Gear Hoists Conform to CMAA, ASME and OSHA guidelines

OVERLOAD LIMIT SWITCH

SATURN offers an Overload Limit Switch that is mounted underneath one of our trolleys as an OPTION. This Overload Limit Switch can be purchased with a NEW hoist or for an EXISTING hoist and installed in the field with minimal effort. This switch is adjusted within 5% and there is no loss of headroom.